Quality

What we offer

Quality Check Points in Process

Raw Material (RM) Arrival from Farmer

QC Check

Visual Inspection,

TSS Measurement,

Visual Inspection,

Raw Material (RM) Arrival from Farmer

The dehydration process begins with the arrival of raw materials, primarily fresh onions, directly sourced from local farmers. We have established trusted relationships with growers in the Mahuva region, known for its fertile soil and ideal climate for onion cultivation.

Washing and Sanitation

QC Check PPM Check

Washing and Sanitation

After quality inspection, the selected raw materials undergo a thorough washing and sanitation process to remove soil, dust, pesticides, and any surface contaminants.

Hot Air Drying

QC Check Moisture Measurement

Hot Air Drying

Hot air drying is a widely used method for removing moisture from materials, especially in food processing, pharmaceuticals, textiles, and other industrial applications.

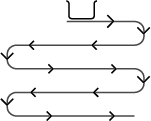

Slicing and Feeding on belt

QC Check Slice thickness checking

Slicing and Feeding on belt

Slicing and feeding on a belt is a process commonly used in food processing and manufacturing industries to prepare raw materials for further operations like drying, frying, freezing, or packaging.

Moisture Measurement

QC Check Dried onion slices are further passed through second stage dryer and get completely dehydrated (Moisture level up to 6%).

Moisture Measurement

Dried onion slices are further passed through second stage dryer and get completely dehydrated (Moisture level up to 6%).

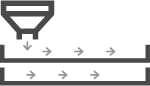

Temperature & Humidity of environment

QC Check Dehydrated onion slices are moved through food grade conveyors at controlled conditioned room & get cooling in a cold dryer.

Temperature & Humidity of environment

Dehydrated onion slices are moved through food grade conveyors at controlled conditioned room & get cooling in a cold dryer.

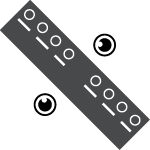

Vegetable impurities ratio checking

QC Check Onion kibbled sorting based on image sensing technology to remove onion roots and other impurities.

Vegetable impurities ratio checking

Onion kibbled sorting based on image sensing technology to remove onion roots and other impurities.

Foreing matter check

QC Check Here onion kibbled, powder & chips are separated & skin is removed by air aspiration.

Foreing matter check

Here onion kibbled, powder & chips are separated & skin is removed by air aspiration.

Metal Pieces verification every 2 hours.

QC Check Sorted Onion kibbled is passed through a metal detector to remove metallic impurities.

Metal Pieces verification every 2 hours.

Sorted Onion kibbled is passed through a metal detector to remove metallic impurities.

Chemical, Physical & Microbiological testing

QC Check Production batch wise product sample is sent to lab testing.

Chemical, Physical & Microbiological testing

Production batch wise product sample is sent to lab testing.

Packing material inspection

QC Check The polybags are packed in paper bags or in corrugated boxes as per customer requirement.

Packing material inspection

The polybags are packed in paper bags or in corrugated boxes as per customer requirement.

Packaging Material inspection, Sealing Check

QC Check Dehydrated onion kibble is packed in moisture proof food grade 2 layer polybags.

Packaging Material inspection, Sealing Check

Dehydrated onion kibble is packed in moisture proof food grade 2 layer polybags.